Diversified product display forms and solutions

We are a manufacturer of magnetic fittings for the precast concrete construction industry .

Who Are We?

Ningbo Mingchuang Magnetic Technology Co., LTD

Our company is located in China’s Yangtze river delta economic center – ningbo city, Zhejiang province, the company covers an area of 1000 ㎡, the company has modern management consciousness of talents and rich production experience, senior engineering and technical personnel, and will be first-class management, advanced technology manufacturing high quality products, with high quality service, good reputation to build corporate image, with high quality, Sincere attitude and domestic and foreign customers common development, create the future!

Let you know me

Team introduction

Our technical sales staff, with years of industry experience, to provide you with valuable help and advice. We provide free 2d or 3D CAD drawings for your designs. Our skilled technicians are the best in the industry and can handle complex solutions

Industry field

We are one of the leading suppliers and service providers in the precast concrete industry. For precast concrete industry production to create innovative process optimization solutions. We produce precast concrete template magnets, embedded embedded magnets, positioning magnets, lifters, inline threaded steel, wavy tubes, side fixed lifters, various precast components and auxiliary materials, widely used in precast concrete precast components, metal and other industrial fields

product category

The company's main brand is "Mingchuang" side template magnet and its connecting fixture supporting components, magnetic strip side die, magnetic box supporting magnetic block and all kinds of pipeline layout precise positioning embedded fixed magnetic seat (rubber tube magnetic seat D40), positioning embedded magnetic seat (D50,D54,D65 magnetic seat), junction box embedded fixed magnetic seat, (type 86, Four box type), corrugated pipe, steel transition plastic bracket, screw thread embedded type magnetic, positioning magnet, lifting components, hoisting rigging, release the crowbar, etc, to the production of precast concrete components with magnetic fixed solutions instead of traditional iron nails or screws, enhances the working efficiency of the workers, save labor costs, magnetic fixed processing can be repeated use frequently, Long service life, simple and convenient maintenance, for the construction industry to bring good economic benefits.

I'll take care of it for you

Focus on precast concrete component production provide a comprehensive magnetic fixation solutions

What Our Customers Say About Us

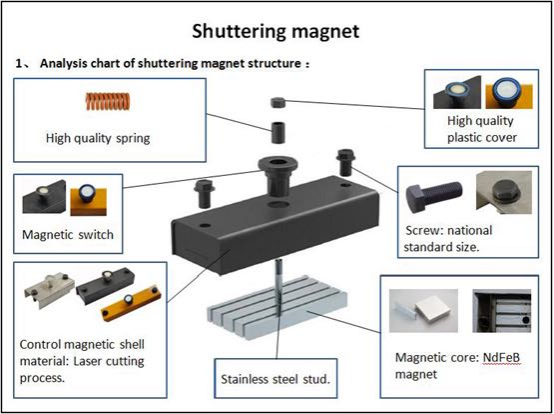

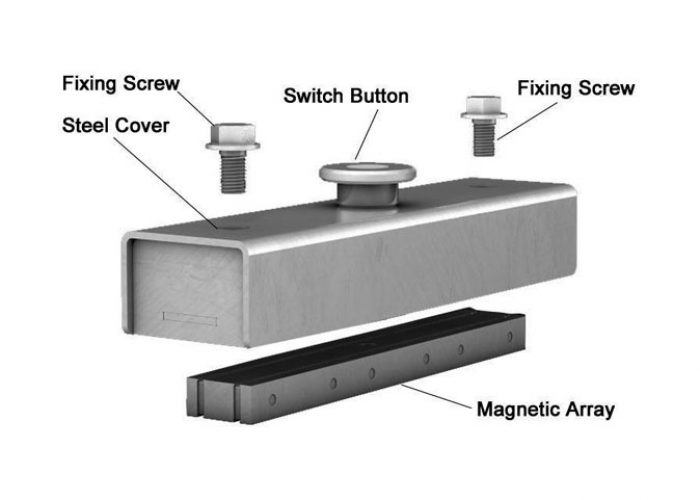

method of application

- The template magnet has a magnetic lever (magnetic switch), the template magnet is placed on the platform, press the switch, the template magnet firmly attracts the platform, in the working state; Using a lever to pry the switch, the template magnet and the platform suction is greatly reduced, the template magnet is closed, you can move the template magnet.

- The thickness of the platform and the smoothness of the surface will affect the suction between the template magnet and the platform, the thicker the platform, the smoother the surface, the greater the suction, and the lateral shear force is related to the template magnet suction and the friction coefficient of the contact surface.

- There are two fixed screws at both ends of the template, which can be connected to different fixtures to fix the side template magnets of different shapes and structures, such as Angle steel, channel steel side die, etc.

- The template magnet of our company uses permanent strong magnetic force. Under the premise of not exceeding the maximum working temperature and not damaging the rust magnet itself, the magnetic force can be maintained permanently in theory.

- Template magnet use of environmental conditions: 1, the environmental temperature is not greater than 80 degrees Celsius 2, the surrounding medium without corrosive metal erosive agent.

I want to hear what you think

European sales representative:

Javier Alvarez:

Phone:+34 610 20 44 12

E-mail :jalvarezbaigorri@gmail.com

Blog:prefabricadoseguro.com